Choosing the right aircraft tug tractor is a critical decision for any airport or airline, impacting operational efficiency, costs, and environmental responsibility. This comparative review analyzes two industry leaders: Eagle Tugs and Oshkosh AeroTech, highlighting their strengths and weaknesses to aid informed decision-making. We'll examine power sources, performance, usability, maintenance, costs, and environmental impact.

Power Source: Diesel vs. Electric

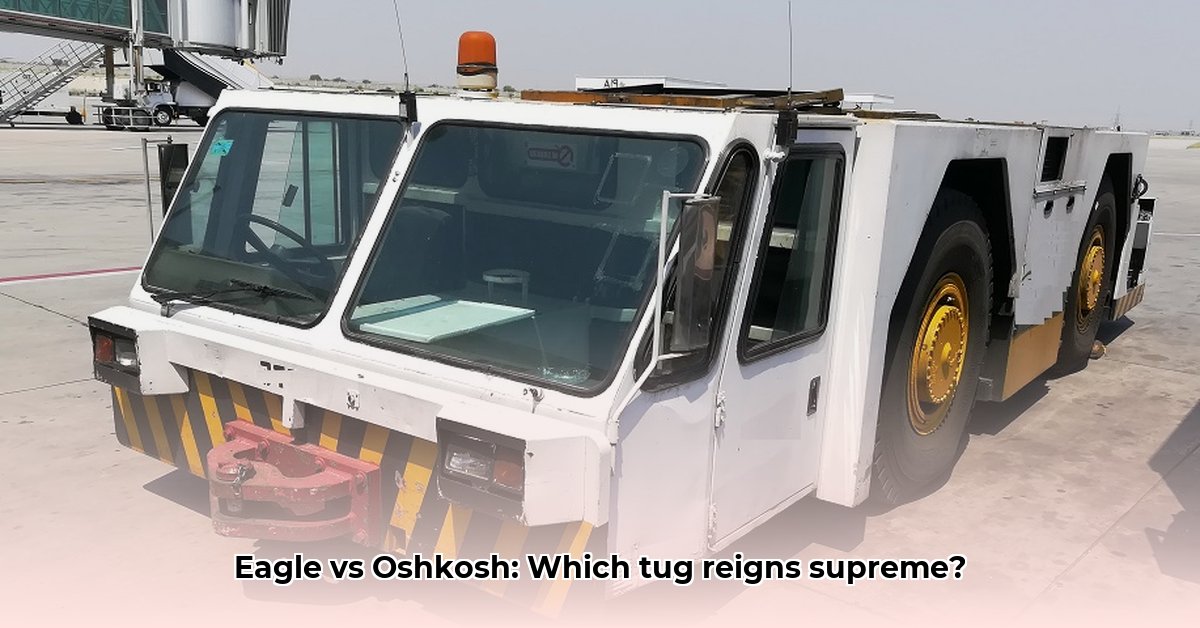

Eagle Tugs primarily employs diesel engines, providing robust power and reliability, akin to workhorses of the aviation industry. This translates to high towing capacity, especially on inclines, but incurs higher fuel costs and greater environmental impact due to emissions. Conversely, Oshkosh AeroTech’s LEKTRO line utilizes electric power, offering quieter, cleaner operation and potentially lower long-term running costs. However, initial investment is higher, and charging infrastructure limitations need consideration. The choice hinges on balancing immediate power needs with long-term cost savings and environmental concerns. Is the upfront cost of electric worth the long-term savings in fuel and maintenance?

Performance: Towing Capacity and Maneuverability

While both manufacturers offer models for various aircraft sizes, detailed performance comparisons remain scarce. Anecdotal evidence suggests diesel tugs often exhibit greater raw power, particularly important for heavy loads or challenging terrain. Electric tugs, however, frequently boast superior maneuverability, ideal for navigating confined airport spaces. The lack of readily available, standardized performance data from both manufacturers hampers a definitive comparison. What is the true towing capacity difference under various conditions?

Ease of Use and Maintenance: Operational Efficiency

Both manufacturers strive for intuitive controls. Ease of use varies between models, necessitating detailed individual model research. Diesel tugs typically require more frequent maintenance. However, repairs are usually simpler and quicker while electric tugs might need less frequent maintenance but more complex repairs that could increase downtime. The optimal choice depends on maintenance team skills and the overall cost-benefit analysis of maintenance procedures. What maintenance procedures and associated costs are unique to each manufacturer?

Cost Analysis: A Comprehensive Breakdown

Upfront costs for electric tugs are usually higher than for comparable diesel models. However, long-term operational costs are typically lower due to cheaper electricity compared to diesel fuel. Accurate cost predictions are difficult given limited publicly available data on long-term maintenance and repair costs. A thorough lifecycle cost analysis, considering energy consumption, maintenance, and potential battery replacements for electric tugs, is crucial for informed decision-making. How do total lifecycle costs of each line of tugs compare?

Environmental Impact: Sustainability on the Ramp

Oshkosh AeroTech's electric tugs possess a significantly lower carbon footprint than Eagle Tugs' diesel counterparts, aligning with the industry's increasing focus on sustainability. However, the environmental impact of electricity generation needs consideration. Future regulations might further favor electric models, making this a crucial long-term planning factor. What are the total emissions generated per year by the average tug from each manufacturer?

Case Studies and Conclusion: Informed Decision-Making

A lack of comprehensive, publicly available case studies comparing Eagle and Oshkosh tugs under identical operational conditions limits direct comparisons. The final choice depends on factors specific to your needs and priorities: budget, environmental targets, operational requirements, available infrastructure for charging electric tugs, and overall long-term cost-benefit analysis. Both manufacturers offer strong products, but increased data transparency from both companies would significantly improve the decision-making process for potential buyers. What are the key considerations for selecting the right tug based on individual airport operational priorities?

Key Takeaways:

- Diesel tugs offer immediate power and high towing capacity at a lower upfront cost, but higher long-term running and maintenance costs.

- Electric tugs offer long-term cost savings and reduced environmental impact, but have higher initial investment costs.

- Detailed performance and cost comparison data is lacking from both manufacturers, making a definitive "winner" impossible to declare.